Client

Ground engineering contractor

Sector

Hospitality & retail

Project Type

Installation

Products Used

MagnaPro IP, SumpFlush IP

Onsite Duration

3 weeks

Location

Mayfair, London

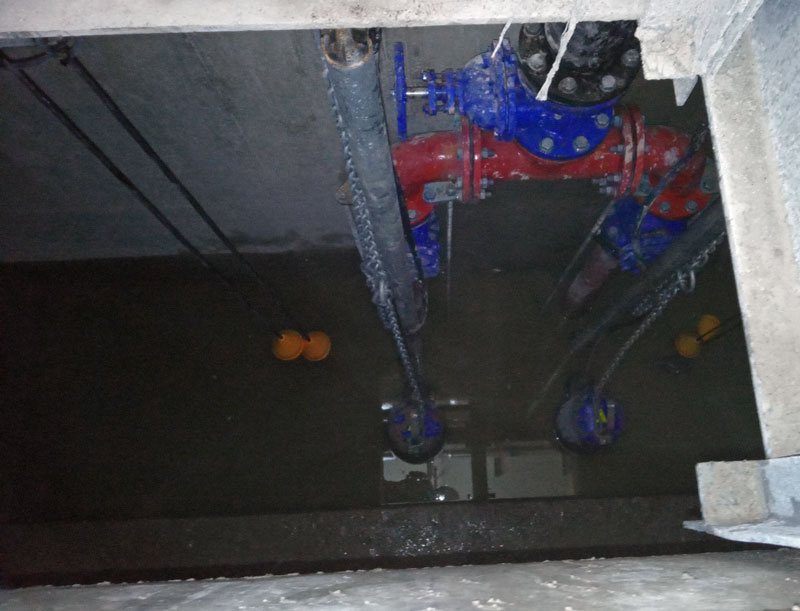

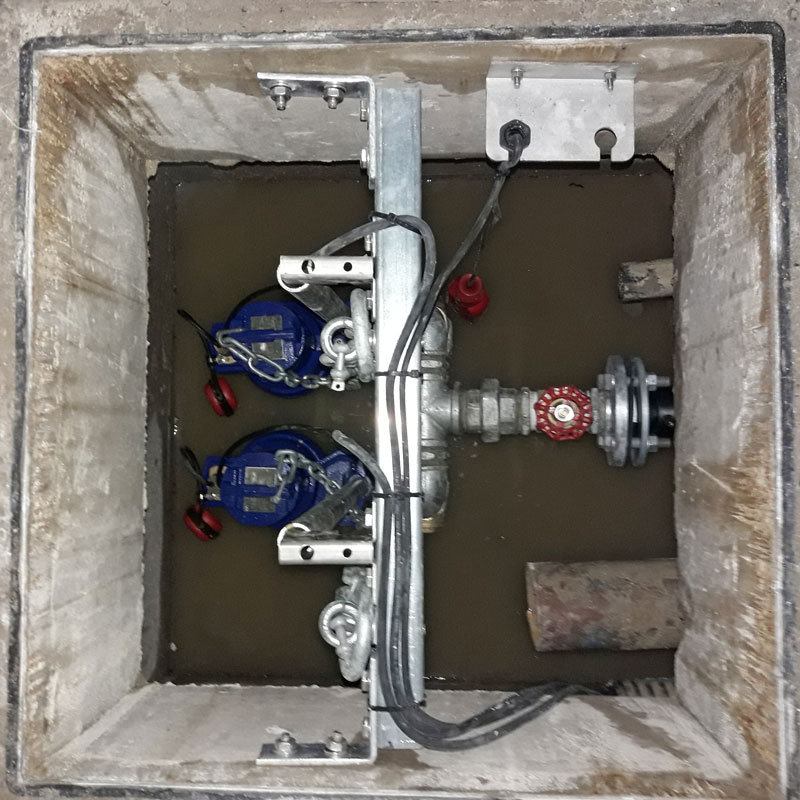

INTRODUCTIONSeven pumping stations were required for a new hotel and residential development in Mayfair, London. The mixed-use apartment and hotel scheme comprises 41 flats, a 51‑bedroom 5‑star hotel, a restaurant, and a luxury spa with indoor swimming pool. We were asked to supply a foul water pumping station, a surface water pumping station and five groundwater stations which would be fed from a cavity membrane system. All pumping stations were to be installed in concrete sumps which had been constructed by our client, a specialist engineering contractor, to a drainage scheme created by the project’s drainage consultant. They would all be situated below floor level of a basement level 3 car park, with a head exceeding 10 m. METHODOur project manager conducted a site survey and assessed the drainage plans provided. Based on these, a specification for the pumping stations was created and a quotation submitted and approved. The foul water pumping station was installed into an approximately 7.5 m(L) x 3 m(W) x 3.5 m(D) chamber which featured a 0.8 m deep pump well. We installed a twin-pump pumping station with DN80 ductile iron pipework, which in turn connects to 110 mm OD HDPE pipework with electrofusion fittings. The pumps provide the necessary self-cleaning flow rate for the required head. The surface water pumping station empties a large concrete surface water attenuation tank which featured a 0.8 m deep pump well. We installed a twin-pump pumping station with DN100 ductile iron pipework, which in turn connects to 110 mm OD HDPE pipework with electrofusion fittings. The pumps can provide the necessary flow rate for the required head. Basement waterproofing is provided by a cavity membrane system feeding into five 1 m³ concrete sumps. We installed twin pump pumping stations featuring powerful and reliable automatic submersible pumps. These discharged into 2” galvanised steel pipework which in turn connected to 63 mm OD MDPE pipework with electrofusion fittings. These stations discharged separately to high level. Each pumping station includes a high-level alarm. The electrofusion fittings provide very homogenous, reliable, and long-lasting joints by melting the surface layer of the pipe to the fitting by application of a computer controlled current to an integral heating element. All the pumping stations’ control panels or high-level alarm feature a volt-free contact for future integration with the development’s BMS for monitoring purposes. RESOLUTIONThe pumping stations were installed to programme. Our project managers and site engineers are experienced in working on busy sites as part of major construction projects. We will submit a service agreement proposal to the owner to provide planned preventative maintenance once the development has completed.

The foul water pumping station.

The surface water pumping station.

One of the five groundwater stations.

The control panels for the foul and surface water pumping stations.

A high level alarm for one of the groundwater pumping stations.

|

|