Client

Property owner

Sector

Residential

Project Type

Refurbishment

Products Used

MagnaGrand IP, Tankering

Onsite Duration

1 day

Location

Watford

INTRODUCTIONWe were asked by a homeowner to inspect a foul water pumping station on recommendation from a major pump manufacturer. The station serves a bungalow in Watford. The homeowner was in the process of selling the property and wanted to ensure that the pumping station was fully operational before the sale. METHODOne of our project managers attended the same day as the initial enquiry to conduct a survey. The pump installation was nearly thirty years old and was in a poor state of repair. The pumps and the pipework were corroded and heavily encrusted with waste. One of the vertical discharge pipes had a large hole in it caused by corrosion. The pumps could run but the station was inoperable due to a float issue. We were not able to determine whether the pumping station had been regularly maintained but were told that the floats had been replaced a year previously. We recommended a full refurbishment including pumps, pipework, floats and control panel. A quote was supplied which included attendance by a tanker to empty and clean the chamber. The order was received from the customer one week later and the work was scheduled for two weeks later. A pump service engineer attended the site to install the new system. Edincare Drains also attended to empty and thoroughly clean the chamber. The old equipment was removed and replaced in the same day. The system was thoroughly wet-tested and was guidance provided on its operation and recommended maintenance schedule. RESOLUTIONIt took only 15 days from initial enquiry to commissioning of the new pumping station. The client was very pleased with the quality of the pumping station and the service received. We will produce an Operating and Maintenance Manual for the new property owner. This will include our recommendations for scheduled preventative maintenance.

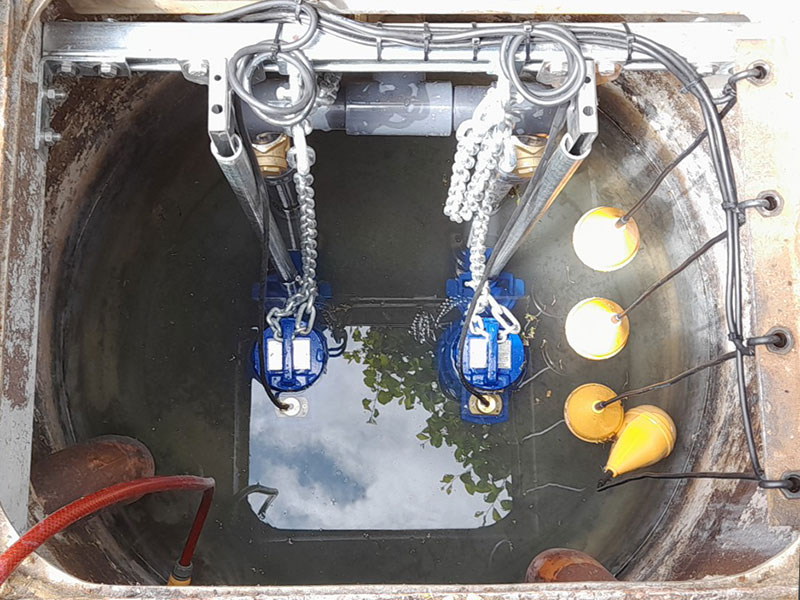

Edincare Drains emptied and cleaned the chamber to allow our pump engineer to work.

The old system after tankering.

The previous system was stripped out. This discharge arm was badly corroded.

The base of the chamber after cleaning by Edincare Drains.

The new PVC Class E discharge pipework was built in situ.

The new system following commissioning.

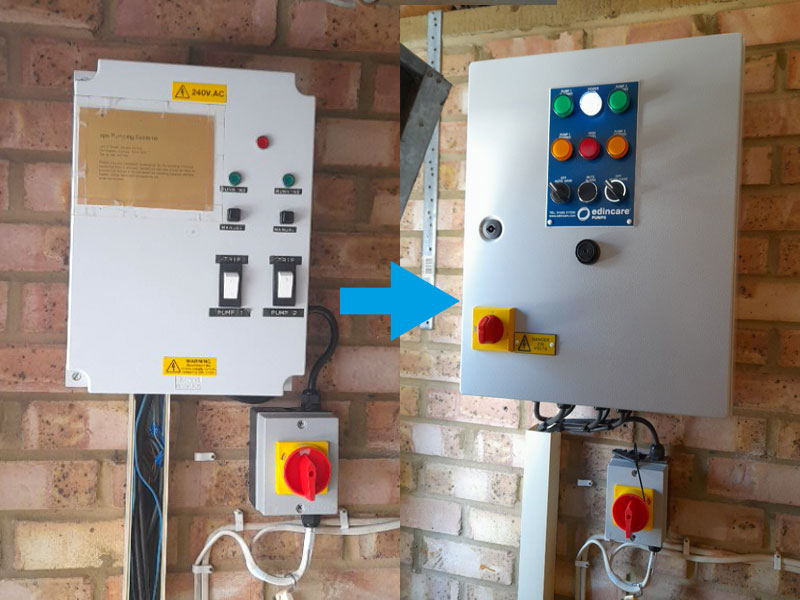

The control panel was replaced.

|

|